Best practice examples

Results 81 to 90 of 148

Best practiceProduct: Save water with the new HXI-HXV closed circuit cooling tower!

The patented flow control system of the HXI – HXV hybrid closed circuit cooling tower by the Baltimore Aircoil Company (BAC) is the ideal solution for medium to large heating, ventilation, and air conditioning (HVAC) and industrial applications. Unparalleled water and cost savings, adaptability to dry, adiabatic or combined wet-dry operation as well as no plume discharge make the HXI – HXV hybrid closed circuit cooling tower by the Baltimore Aircoil Company (BAC) ideal for a range of applications. The patented intelligent flow control system with a 3-way valve allows customers to remarkably reduce annual water consumption (by up to 70%). Depending on local water costs, the flow control system alone can pay for the HXI – HVX hybrid unit in as little as two years. As with all BAC cooling towers, the HXI – HXV model is independently certified by the Cooling Technology Institute (CTI), hereby ensuring that published thermal capacities reflect actual thermal performance. This eliminates the need for customers to perform costly individual cooling tower testing. …

Best practiceProduct: SLVE Compressors for R290 (Propane)

Secop's most powerful variable speed compressor for propane is the ideal choice for commercial applications like soft scoop ice cream displays, reach-in merchandiser multidecks, refrigerated display cases, stainless steel reach-in freezers and large glass door merchandisers. Secop's ultraefficient SLVE18CN compressor uses the environmental friendly refrigerant propane (R290) with a low global warming potential (GWP3). The SLVE18CN is the most powerful hermetic reciprocating variable speed compressor for propane available on the market. The compressor achieves more than 2 kW cooling capacity and a COP of up to 2.25 (ASHRAE MBP) while operating continuously inside an evaporating temperature range from -45 to +10°C. …

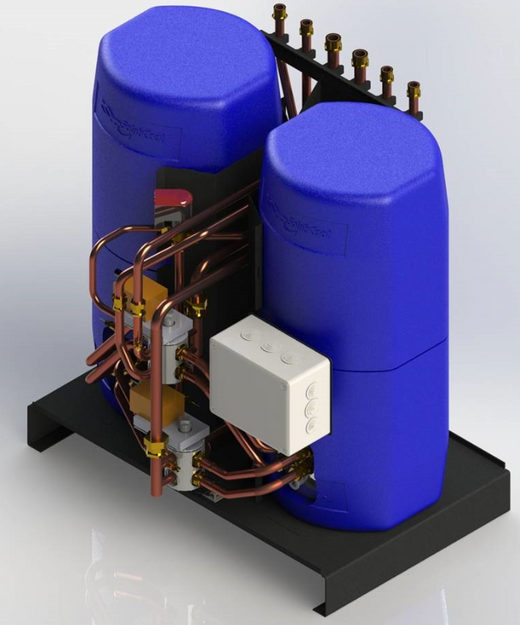

Best practiceProduct: SolabCascade: Heat-driven cooling

The SolabCascade developed by SolabCool uses excess heat to provide energy-efficient cooling. Water is used a natural coolant to distribute the cooling within office buildings, nursing homes, hotels, or other commercial applications. The SolabCascade is a compact cooling system that operates on the principle of sorption cooling. It uses excess heat from district heating networks, solar power generators or combined heat and power systems – energy that would otherwise be lost. The SolabCascade requires no additional electricity supply, hereby greatly reducing operating costs and carbon emissions. It is a modular and scalable system with a maximum power of 5kW. …

Best practiceProduct: SolabChiller: Heat-driven cooling

The SolabChiller developed by SolabCool uses excess heat to provide energy-efficient cooling. Water is used a natural coolant to distribute the cooling within private housing or small commercial applications. The SolabChiller is a compact cooling system that operates on the principle of sorption cooling. It uses excess heat from district heating networks, solar power generators or combined heat and power systems – energy that would otherwise be lost. The SolabChiller has a 75% lower electricity consumption compared to conventional air conditioning systems, hereby greatly reducing operating costs and carbon emissions. The SolabChiller has a thermal efficiency of 6 and is available with a maximum power of 2.5 or 5 kW, dependent on the type of cooling requirement. …

Best practiceProduct: Solar cooling

Working with academic institutions across Europe, Solar Polar have developed off-grid solar thermal powered absorption cooling systems for air conditioning, refrigeration for vaccines and food storage purposes. The cooling systems may be mounted on the roofs or walls of buildings or even in open spaces. Several appliances may be joined together to satisfy the required cooling load, especially in regions prone to prolonged periods of cloud cover. …

Best practiceProduct: Solar-powered ice machines

ZIEGRA Ice Machines from the propane (R290) CoolNat series use battery-buffered solar power to supply ice for food preservation, such that they are ideal for use in regions that have no or very unreliable power supply. …

Best practiceProduct: SolarChill (Solar-Powered Vaccine Cooler)

Global Technological Breakthrough for Solar-Powered Vaccine Coolers Driven by the International “SolarChill Partnership" in Terms of Storing Vaccines in Areas without Regular Power Supply. The Vestfrost SolarChill vaccine refrigerator with the Secop Solar Compressor was the first device to be tested and approved by WHO. Since then, Vestfrost Solutions has delivered a significant number of refrigerators for vaccine programs all over the world. …

Best practiceProduct: STRATOS air-cooled chillers

The STRATOS series from Secon is the flagship among the air-cooled propane chillers. The series covers cooling capacities from 150 to 1,200 kW and can be used in a wide temperature range with discharge temperatures from +20 to -30°C. As standard, the units can be operated at ambient temperatures from -20 to +40°C (tropical version available on request). LT models use propylene (R1270), which is also a natural refrigerant. The units can be equipped with 1 to 4 reciprocating pistons or 1 to 2 screw compressors. The capacity control is either stepped or stepless with inverters. The units already have a special, highly developed control system as standard. Optionally, they can also be equipped with a Siemens S7 industrial control system. All units are designed specifically for the project and can be equipped with various options (pumps and/or hydraulic modules, heat recovery or free cooling). …

Best practiceProduct: Sustainable household refrigeration with R600a

The Electrolux SC300 is a completely F-gas free domestic refrigerator. The energy efficient system uses R600a and is rated with A+++ for the European Energy Index. The SC300 only uses around 71kWh per year. A quick-cooling function, attractive LED lighting and the spacious SpacePlus drawer offers a user-friendly and efficient cooling solution for your domestic needs. …

Best practiceProduct: The LTC 30e Plus - One of the most efficient chillers on the market

All basic components for thermal cooling are included in one device: Invensor’s LTC 30e Plus. With a maximum thermal coefficient of performance (COP) of 0.72 and an outstanding maximum energy efficient ratio (EER) of 33, the LTC 30e Plus remains one of the most energy efficient chillers on the market. An automatic power adjustment allows cooling capacity ranging from 10 to 35 kW. With an integrated system controller, the LTC 30e Plus provides a range of options to meet individual customer needs and applications. The system is controlled remotely via ethernet, and comprehensive measurement technology facilitates installation and operation. A hydraulic unit with powerful high-efficiency pumps directly connects all hydraulic circuits for the driving energy, cooling distribution and recooling. …