Policy instruments

Policy instruments

Currently, the cooling sector accounts for up to 10% of global greenhouse gas emissions (EIU, 2019) (opens in a new window). This makes it one of the key sectors for combating climate change. The switch to Green Cooling is no longer just a decision of the consumer or the manufacturer: it is a political issue.

The political realm understood early on that national solutions are not sufficient in the fight against climate change. Global warming knows no borders. It is therefore important to set climate targets within international agreements to achieve the most far-reaching success.

International treaties

Text

International treaties such as the Paris Agreement and the Montreal Protocol form the basis of our work. They are often supplemented by national and regional instruments. These include, for example, bans on certain refrigerants or financial incentives when investing in sustainable cooling systems. Click on the boxes below to find out more!

Accordion

Regulating refrigerants: bans and quotas

Bans and quotas

Bans

A ban restricts the use of certain refrigerants according to their GWP. For example, refrigerants with a GWP above 150 in passenger car MAC systems have been banned in the EU since 2017. HCFCs are completely banned in the EU. The revised F-Gas Regulation also bans refrigerants above a certain GWP with a fixed phase-out schedule.

Quotas

Quotas limit the quantity of certain refrigerants within a country or a specific refrigeration or air conditioning sector within a country. Quotas can relate to production, import/export or consumption. Import/export quotas are often preferred because they are easier to implement. In many cases, the total amount of refrigerants allowed is then divided between the different industrial players.

Increasing energy-efficiency: labelling and MEPS

Increased energy efficiency

Emissions from powering cooling appliances, which originate from the generation of energy, are best addressed through energy labelling and minimum energy performance standards (MEPS).

Energy labelling, where the energy consumption of a unit and its placement in the efficiency ranking of all available appliances is prominently displayed, is often the first step towards increasing the energy efficiency of electrical appliances. Consumers are able to make informed purchasing decisions, which include the running costs over the appliance’s lifetime and can therefore lower energy bills. Labelling alone is therefore an incentive for companies to produce more energy efficient appliances. The market share of higher efficiency appliances will increase.

A second step is the introduction of MEPS, which ban appliances below a certain level of energy efficiency. Often this means that the lowest class or classes of the labelling scheme are banned. Many countries have successfully demonstrated that labelling and MEPS for refrigeration and air conditioning appliances can be very effective in reducing the energy consumption and carbon footprint of these appliances.

Improving safety: standards, certified personnel & leakage controls

Improved standards

Standards

Standards are principally technical specifications as a voluntary self-commitment of the industry. They are not mandatory; however, international standards are often adopted as national standards and sometimes made into laws especially in developing countries without their own standardisation bodies. With regards to refrigeration and air conditioning systems, existing standards dealing with safety are especially relevant. However, they may present a barrier to the introduction of Green Cooling because they impose obstructive refrigerant charge size limits.

A positive correlation between refrigerant quantity and cooling capacity is demonstrated for natural refrigerants, such that there is an explicit need to modify international safety standards to allow larger charge sizes. In order to offset the increased flammability risk associated with a greater allowable charge, additional safety measures to mitigate the risk can be introduced to cooling systems. These include improving the system’s leak tightness, assuring sufficient airflow, adopting equipment housing design and inclusion of valves. It is crucial that any changes to existing safety standards or requirements of entirely new safety standards should initially remain voluntary, as requirements are onerous by nature.

For more information on this topic, please refer to our guideline “International Safety Standards in Air Conditioning, Refrigeration & Heat Pump” (2018). (opens in a new window)

Certified personnel

Improper installation and maintenance of cooling units can lead to less energy efficiency, higher leakage rates of refrigerant, breakdowns and premature system end of life. This results in greater direct (refrigerants) and indirect emissions (energy consumption) and higher costs for the operator or user. A better trained workforce helps reduce those problems. Training on the use of natural refrigerants can help improve technicians' health, their working conditions and secure their incomes. Key elements of a successful transition to sustainable cooling technologies are the establishment of standards, an official training path, as well as the certification and registration of technicians country-wide.

For more information on this topic, please refer to our brochure “Fit 4 Green Cooling” (2020) (opens in a new window).

Leakage controls

In order to limit refrigerant leakage, system operators may be subject to regular inspections or be required to monitor leakage rates. The proper use and maintenance of equipment generally limits leakage and improves energy efficiency. It may be appropriate to commit system operators to employ qualified and certified personnel for the use and maintenance of certain devices.

Keeping track: (mandatory) reporting

Reporting

To limit the global warming and ozone depleting impact of refrigerants used in cooling appliances, many countries have introduced mandatory reporting regarding the use of refrigerants and the operation of systems and appliances. In Canada, manufacturers and suppliers of HFC refrigerants are required to report all HFCs if they exceed 100 kg in a calendar year. This information is used to determine whether restrictions should be imposed.

Considering the whole life cycle: destruction regulations

ODS Banks

Refrigerants that are toxic or have a high ODP or GWP may need to be extracted at the end of the equipment's life. They must then be properly stored, recovered or destroyed. Take-back systems can ensure the proper treatment of recovered F-gases. They are likely to be more effective if neither the maintenance company that returns the gas nor the producer has to pay a fee. Such systems could be financed by taxes on the import and production of F-gases.

Lending a helping hand: economic incentives and taxes

Financing

Financial instruments include for example economic incentives such as discounts on Green Cooling appliances or taxes based on CO2 equivalents, so that refrigerants with higher GWP are taxed higher. In some countries, such as Norway, there is a refund of taxes if the refrigerant is returned for recycling or destruction.

The RAC sector faces a challenge in the implementation of effective finance strategies given its cross-sectoral nature. It is therefore important that countries develop integrated investment strategies that adequately combine and/or complement support activities to reduce HFC emissions with effective energy efficiency measures. It is furthermore essential that within an integrated RAC sector strategy different funding sources and actors (domestic and international) are identified that can match the diverse financing needs according to their mandates.

For detailed information on this topic, please refer to our guideline “Coordinating finance for sustainable refrigeration and air conditioning” (2018). (opens in a new window)

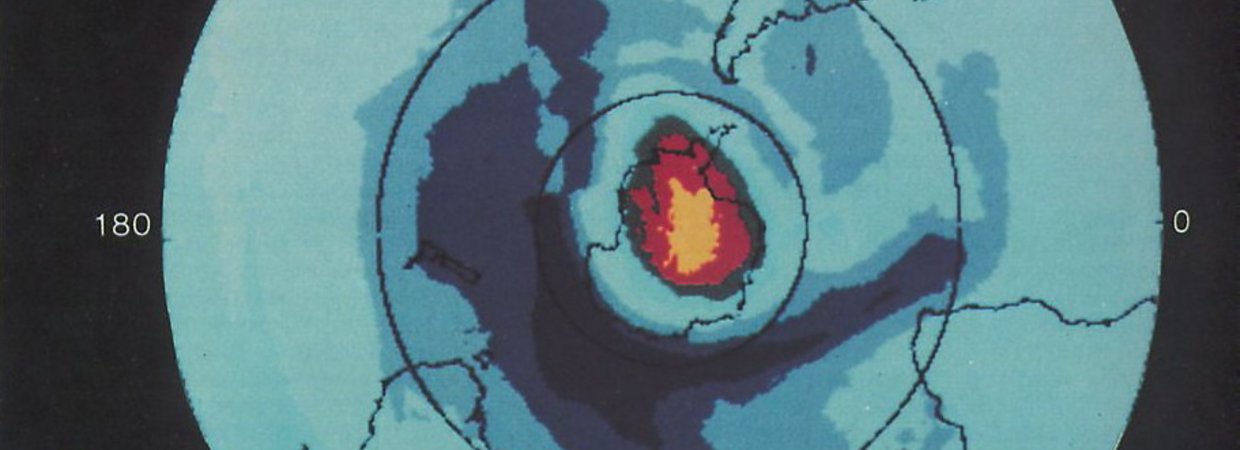

Image: NASA licensed under CC BY 2.0

Image: NASA licensed under CC BY 2.0