A week-long training programme in Germany in May provided policy makers from around the world with a unique learning experience focused on ozone and climate protection.

The training programme struck a balance between technical content and thematic input to suit the diverse backgrounds of the participants. It aimed to improve their understanding of the technical aspects of Green Cooling while providing relevant knowledge for their policy role.

The participants work as National Ozone Unit Officers (NOU) or climate focal points within ministries and governmental bodies of their respective countries from around the world. 13 countries from South America, the Caribbean, Africa, Europe and Asia were represented in the training at the vocational training center Bundesfachschule Kälte-Klima-Technik (BFS) in Maintal, close to Frankfurt, Germany.

During the training, participants had the opportunity to use their senses in various activities such as smelling, hearing and feeling to enhance their understanding of natural refrigerants in the cooling sector.

Smelling ammonia

A visit to the Wilhelm Brandenburg sausage factory taught participants the importance of detecting even the smallest leaks in ammonia-based cooling systems. The participants discovered that leaks can be recognized by the distinct smell of ammonia long before the amount of gas gets dangerous. This hands-on experience highlighted the importance of early detection to avoid accidents. Another trick to avoid dangers: the cooling system of Wilhelm Brandenburg consists of two parts. An ammonia system is installed outside the production halls. It cools down a harmless liquid that runs through the production halls and cools the meat. This two-part system avoids that the meat gets poisoned in the case of a leak.

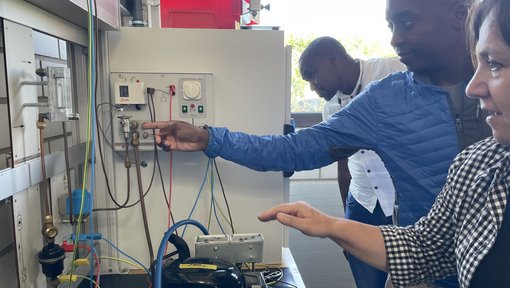

Listening to CO2

In another activity, participants encountered an air conditioning system filled with R744 (CO2). They were instructed to start the process slowly to prevent the CO2 from turning into dry ice that could clog the hose. By listening carefully, the participants, were able to hear the sound of the flowing gas, highlighting the importance of careful monitoring during the operation of cooling systems.

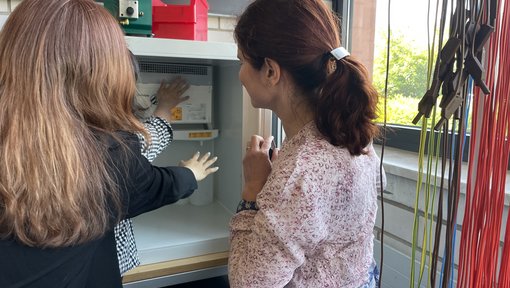

Touching propane cooling

In another lesson, the trainer, Reiner Mayers of BFS, showed how to fill a refrigerator model with propane. The participants tested by touching if it was successful: the refrigerator components, including the hoses, became extremely cold, illustrating the effectiveness of propane as a refrigerant.

By incorporating these sensory experiences, the training programme provided a comprehensive and immersive learning environment. The NOU and climate focal points gained a deeper understanding of the practical aspects of refrigeration systems so that they can make informed decisions and develop effective measures to protect the climate and the ozone layer.

The technical expertise was complimented with policy-oriented presentations. The Cool Training thereby contributed to the development of a well-rounded approach to ozone and climate protection at the government level.

Supported by…

Due to the diverse origins of the participants, the training was financed in different parts by different projects commissioned by the Federal Ministry for Development and Cooperation (BMZ), the Federal Ministry for the Environment and Consumer Protection (BMUV) and the Federal Ministry for Economic Affairs and Climate (BMWK) of the Republic of Germany (in the context of the International Climate Initiative), and by the European Union (EU).