Best practice examples

Results 121 to 130 of 148

Best practice Seminar: Seminar on the heating, ventilation and air conditioning sectors in Sydney, 2015

November 2015: The Australian Refrigeration Association (ARA) hosted a two-day seminar in Sydney to explore the possible contributions of the heating, ventilation and air conditioning (HVACR) industry in reducing greenhouse gas (GHG) emissions. Industrial, commercial and residential HVACR stakeholders were invited to an intensive two-day program highlighting the transition of the Australian HVACR industry to energy efficiency and emissions reduction. The ARA has estimated that Australia has the potential to reduce its HVACR energy bill and operating costs by over $10 B per annum and reducing national GHG emissions by 7% from the HVACR sector alone. The seminar addressed key issues impacting the Australian HVACR industry, providing stakeholders an opportunity to gain accurate information in the following areas: Exploring emerging HVACR energy efficient technologies and solutions Identifying and appreciating energy efficiency and GHG emissions reduction Quantifying and Recognising the value of integrated energy efficient engineering Recognising the regulatory requirements to shift to low GWP refrigerants Safety, risk and education – handling and implementing low GWP natural refrigerants …

Best practice Solar chill, self chill units

Vaccine refrigerator …

Best practice Success story: Air conditioning for world’s largest female-only university in Saudi Arabia

CAREL’s evaporative ChillBooster accommodates comfortable learning conditions in the world’s largest female-only university, the Princess Nora bint Abdulrahman University in Riyadh, Saudi Arabia. The ChillBooster is an evaporative cooler which cools air and lowers its average condensing pressure before the air is used by the condensing units such as chillers or dry coolers. Spontaneous evaporation is favored by the atomization of water in micrometric droplets, reducing the thermal energy required for evaporation from the surrounding air. Having opened in May 2011, the Princess Nora bint Abdulrahman University has a capacity of 50,000 students and hugely promotes female education. The ChillBooster guarantees a higher absorption ratio and less hygiene problems compared to the appliances typically used in such situations. …

Best practice Success story: All-in-one heating, cooling and air conditioning in retail giant Kaufland

Frigo-Consulting has installed an integral CO2 system in retail giant Kaufland’s new large-scale store in the suburbs of Germany, Berlin. The integral CO2 system is a lighthouse project, as it cools, heats and ventilates without needing additional energy. It uses waste heat produced during refrigeration to heat and ventilate the entire Kaufland building. 25-30% less energy is consumed compared to traditional installations, as well as a reduction of the CO2 footprint by 35-40%. The system can adapt to a range of operation needs, e.g. summer vs. winter temperature, working days vs. weekends, etc. Frigo-Consulting took the lead in the project engineering and provided a customized future oriented concept. Since the first installation in 2014, Frigo-Consulting has successfully engineered and commissioned several integral systems. …

Best practice Success story: CO2/ammonia cascade systems

Research and Training Platform using natural refrigerants with particular emphasis being laid on the use of CO2 as refrigerant. A research and training platform using CO2 as refrigerant has been installed at the Université des Mascareignes in Mauritius. This project has been financed through the HPMP (HCFC Phase Out Management Plan) for Mauritius through the Ministry of Environment. The system has been designed to operate in three different modes: Ammonia in direction expansion, a Cascade CO2 operation with Ammonia Cooling the CO2 and CO2 in transcritical mode. The system is completely instrumented with temperature and pressure sensors as well as flow meters to enable trainees to do different kinds of manipulations. …

Best practice Success story: Demonstrating climate benefits of a HCFC phase-out in Bangladesh

In November 2015, Walton launched a new line of refrigerators that run on the natural refrigerant isobutane. The project was supported by the United Nations Development Programme under Bangladesh’s national HCFC phase-out management plan (HPMP). The market transition to green cooling technologies will avoid 65 MT of HCFC-134a emissions annually, as well as savings of about 14 million kWH annually. The project was successfully completed by the end of 2016, and was implemented in a cost-effective and safe manner. …

Best practice Success story: Double Effect Absorption Chiller Jordan

Fresnel-solar Cooling system for industrial facility in Jordan Industrial Solar GmbH provided a Fresnel collector field with a total capacity of 700 kW(th) to an industrial facility in Jordan. Besides process heating the solar steam also powers a double effect absorption chiller which is directly connected to the central cold supply of the facility. …

Best practice Success story: first CO2 training facility in South Africa

Johannesburg, February 2016- Commercial Refrigeration Services (CRS) has opened the first ever CO2 training facility and showroom in South Africa. The new facility is used to train local technicians and contractors on installing and maintaining CO2 systems. Groenwald, CRS’ head of engineering, manufacturing and installations said that “knowledge and experience are the barriers standing between CO2 refrigeration applications becoming the mainstream solution for the African market”. The readily accessible CO2 facility in Johannesburg is helping local technicians to understand the climate-friendly and energy-efficient efficient alternative refrigerant. The facility resembles a small supermarket with three different CO2 refrigeration systems: a booster system, a booster system with parallel compression and a booster system with parallel compression and an ejector. By measuring and analyzing the energy consumption by the different types of systems, CRS may demonstrate to the end users the monetary, energy and ecological benefits of each CO2 refrigeration system. …

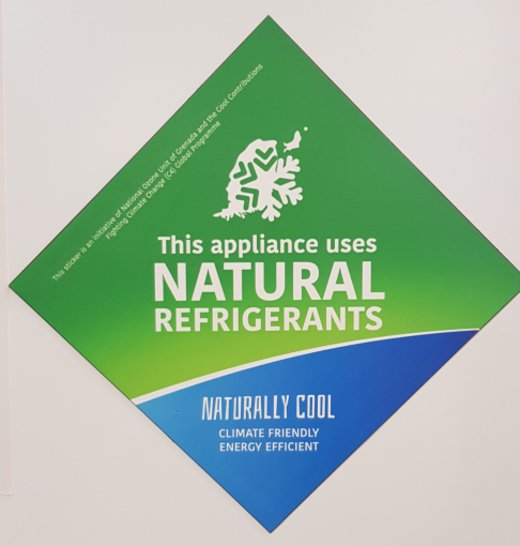

Best practice Success story: Green Cooling labels for refrigerants in Grenada

Since May 2018, the National Ozone Unit (NOU) of Grenada, in cooperation with GIZ Proklima, has been providing Green Cooling stickers to local appliance stores in order to promote the dissemination and use of natural refrigerants on the island state. The initiative created by both project partners supplies local appliance stores with eye-catching green magnetic stickers which are fixed on refrigeration systems with natural refrigerants. As a result, both the distributors and the customer alike are provided with a convenient tool for the promotion and distribution of natural refrigerants, and thus for ozone and climate protection. First piloted with the two companies Courts Grenada Limited (UNICOMER) and L. A. Purcel, the NOU aims to involve more retailers and suppliers and expand the initiative also to air conditioning technologies, with the goal of eventually making Grenada the first f-gas-free Caribbean island. …

Best practice Success story: Green Cooling labels for refrigerants in Grenada

Since May 2018, the National Ozone Unit (NOU) of Grenada, in cooperation with GIZ Proklima, has been providing Green Cooling stickers to local appliance stores in order to promote the dissemination and use of natural refrigerants on the island state. The initiative created by both project partners supplies local appliance stores with eye-catching green magnetic stickers which are fixed on refrigeration systems with natural refrigerants. As a result, both the distributors and the customer alike are provided with a convenient tool for the promotion and distribution of natural refrigerants, and thus for ozone and climate protection. First piloted with the two companies Courts Grenada Limited (UNICOMER) and L. A. Purcel, the NOU aims to involve more retailers and suppliers and expand the initiative also to air conditioning technologies, with the goal of eventually making Grenada the first f-gas-free Caribbean island. …