Search

Search form and result list

Results 1 to 10 of 907

ProjectAccelerating Air Conditioning Transformation through Enhanced Energy Performance Standards

06.05.2024 News From Zero Interest to Net Zero: Retail Banking for Energy Efficiency, Philippines

A training workshop in the Philippines offered the opportunity to find solustions to create more incentives for consumers to invest in energy efficient and climate-friendly appliances. Like this the cooling sector in the country should be able to fulfil its crimate targets.

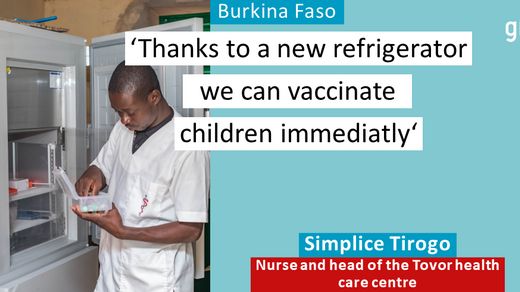

10.05.2024 News Burkina Faso: 11000 people immunized thanks to climate-friendly refrigerators

The ROCA project donated climate-friendly vaccine refrigerators to ten health-care centres in Burkina Faso.

MemberCosysense

Ablehnung kein Bezug zu nat. Kältemittel /Cosysense provides a net zero service to commercial buildings like office and coworking spaces. Our plug-and-play sensors collect user comfort data, indoor environment, and HVAC power that we transform into real-time CO2e emissions. We complement it with databases of outdoor temperature, weather conditions, grid emission factors, and electricity price. We record all information in a serverless database and visualise it in digital dashboards. Our AI model uses the data for dual comfort and energy optimisation every 15 minutes. This represents the dynamic nature of buildings and people’s comfort needs. Looking ahead, we will add dynamic pricing and grid emission factors into the optimisation model for future grid-connected smart buildings. Our AI executes HVAC adjustments through battery-powered wall panel attachment that can be installed to approx. 80% of single and multi-split HVAC models with infrared or manual controls. We can install all our non-invasive devices in 1h without cutting a single cable in clients' spaces. Cosysense creates above 15% power and emissions savings on top of any other IoT existing solution. It has no upfront cost because we lease our sensors for free. Clients pay a subscription fee between $19 and $99 per sensor per month only if the savings we generate are larger than our fee. That is how our clients become more profitable and greener with our solution. …

MemberMAGNOTHERM Solutions GmbH

MAGNOTHERM is an emerging university spin-off from Technische Universität Darmstadt with world leading expertise in permanent magnets and magnetic cooling. Our technology, based on solid state materials and water, is capable of replacing standard gas compression cooling or heating solutions in compliance with current and future f-gase regulation standards. Our developed cutting-edge energy conversion solutions allow cooling and heating with low pressure systems (approx. 0.5 bar) and is 40% more efficient than current systems. At the same time it complies with all current and future EU F-gas regulations, is explosion free and non-flammable. It is efficiently scalable in all sizes (from 0.5 to 5 kW) for thermal energy conversion units in decentralized, mid-range powered applications. With our 100% green technology, we are able to meet the world’s fast growing demand of clean and sustainable cooling and heating applications. …

23.01.2024 News COP28: Recap and Highlights

The Montreal Protocol Pavilion at COP28 showcased the Montreal Protocol's achievements in climate protection. GIZ Proklima participated as one of 16 partners, aiming to advance Green Cooling. For the first time, the pavilion provided a platform for the Montreal Protocol and the cooling community to promote climate action. The Ozone to Cool Zone pavilion aimed to spread awareness, scale efforts, and unlock innovation for solutions to minimize the cooling sector's negative climate impacts, advance sustainability goals, and unlock more effective solutions. All materials of the side-events can be found here.

12/2023 PublicationCOP 28 RAC Skills Side Event Highlights Philippine Innovation in Green Jobs through Climate-Friendly Cooling

The Philippines highlighted its best practice on green jobs in climate-friendly cooling through the COP 28 hybrid side event “Skills in Refrigeration and Air Conditioning with Growth in Global Cooling Demand” at the Philippine Pavilion on 08 December 2023.

30.04.2024 News Senegal: Trainings in Green Cooling

Assane Thiam and Fatikha Ba, along with 98 other refrigeration and air conditioning professionals, have successfully completed a training course focusing on the use of natural refrigerants, which are less harmful to the environment and more energy-efficient.

26.04.2024 News Grenada Steps Closer Towards the Establishment of a Product Registration System for Cooling Equipment

Grenada solidified its commitment for a market transformation to energy efficient and climate friendly cooling solutions with the successful hosting of a workshop on the establishment of a Product Registration System for Cooling Equipment.

29.04.2024 News NDC4 Webinar Series Shares Tools, Methods and Best Practices for Integrating the Cooling Sector into NDCs

As part of the global project Cool Contributions fighting Climate Change II (C4 II), a series of webinars has been initiated to address a critical aspect of climate action: integrating the cooling sector into Nationally Determined Contributions (NDCs). The sessions serve as a platform to disseminate tools, methods and best practice examples to incorporate cooling strategies into the national climate commitments under the Paris Agreement, highlighting the pivotal role of the cooling sector in achieving these targets.