Search

Search form and result list

Results 301 to 310 of 907

20.08.2021 News Cool Talks: "We have been fans of natural refrigerants for 125 years"

Monika Witt is an enthusiastic advocate of natural refrigerants, not least in her role as Managing Director of a long-established German refrigeration company and board member of eurammon. We spoke to her about her motivation, her role in the family-run business and why we need a reality-check for safety regulations.

MemberSteinbeis Transfer Center Refrigeration and Air Conditioning

Scientific consulting and support with the use of natural refrigerants. Scientific support with the implementation of thermal energy storage systems. Assistance with the use of ice slurry. Advisory services in the field of solar cooling. Technology transfer in the field of energy efficiency programs involving refrigeration and air conditioning systems. …

MemberInstitute of Green Growth Solutions

Institute of Green Growth Solutions (IGGS) is a registered non-governmental, non-partisan, independent policy think tank that promotes a sustainable approach to development through research, technical assistance, capacity building and advocacy. Our team of internationally recognised and interdisciplinary team of experts with vast experience in the fields of mining, agriculture, natural resource management, environmental science, politics, economics, finance, social science, and geology bring on board diversity and experience in achieving information based results and solutions that not only address environmental challenges but are also a catalyst for sustainable development. …

MemberBrentwood Tech and Development Ltd.

The company consults for the UN on energy efficiency in refrigeration and air conditioning. Founder Nigel Cotton also was a founding member of the European Technology and Innovation Platform on Renewable Heating and Cooling, endorsed by the European Commission. In addition, he founded solarthermalworld.org, which includes a section on solar cooling. …

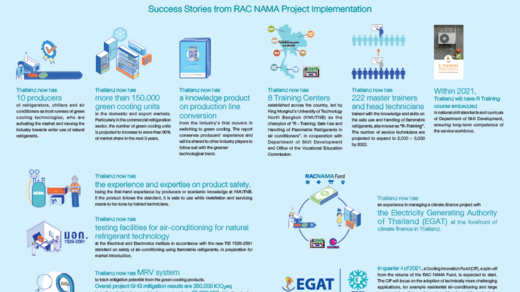

08/2021 Publication - Technical PublicationThailand: MRV Tool guidelines

Greenhouse gas emissions must be (1) monitored, (2) reported, and (3) verified. The guidelines here explain what must be considered in implementing the MRV scheme.

08/2021 Publication - Leaflets & FactsheetsThailand: Success stories of the RAC NAMA project

In June 2021, the RAC NAMA project in Thailand came to an end. This factsheet shares some of the chapters that have been written in the success story that is the RAC NAMA project.

MemberKeren Energy

KEREN ENERGY has developed a holistic approach to saving energy: an Energy Diet based on the equipment that the user already has. In this case, the monthly energy bill is the “scale” of success. The real game changer is the public awareness and participation. Today, people can start weight loss diets to look better, but with the “National Energy Diet” we all can be on our way to a much better, sustainable, and economical life. Furthermore, Keren Energy provisions the Clima-Med project. The project is funded by the European Union and seeks to support the transition of eight partner countries in the South Mediterranean region towards sustainable, low-carbon and climate-resilient development. More info: https://www.climamed.eu/ …

MemberKTH

At the energy lab here at KTH, we are developing efficient HVAC systems and applications as well as waste heat recovery systems such as heat pumps and geothermal applications. Our research projects concern the design of refrigeration and heat pump systems, and what can be done to make these systems more energy efficient and their environmental footprint smaller. To obtain the previously mentioned added values, we build, commission, and test specific projects investigating how natural fluids, like propane, carbon dioxide, and ammonia, could be used in a safe and efficient way as refrigerant. Refrigeration systems and heat pumps, especially High Temperature Heat Pump (HTHP), become more efficient if the heat exchangers, evaporator and condenser, are efficient and give small temperature differences. For this reason, we have research projects on enhancing the surface area to volume ratio of the heat exchangers using additive manufacturing technologies (Metal 3D Printers) to attain the best ratio. …

MemberKOR AZ Consulting Eng. Ltd.

Refrigeration & HVAC consulting engineering company, for commercial, institiutional and industrial systems. KOR AZ Consulting Eng. Ltd. is a consulting engineering firm, encouraging the use of natural refrigerants, especially ammonia and carbon dioxide, by recommendations to our customers to use these refrigerant for commercial and industrial refrigeration systems. We are explaining the advantages of natural refrigerants, and the limitations of using the HFC refrigerants according to the global and local standards. …

MemberElectroland ghana ltd

ELECTROLAND Ghana Limited is the sole distributor of Samsung Electronics, Midea, Toshiba Appliances, ABB electricals and brand owner of NASCO electronics in Ghana. In the field of sustainable refrigeration, ELG offers various refrigerators from Nasco, Midea and Toshiba, all of which use the environmentally friendly refrigerant R600a. With over 15 years of experience in consumer electronics, ELG is committed to bringing the latest technology to your home and enriching the lives of individuals, households, offices and the hospitality industry in Ghana. …